- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

- E-Service

|

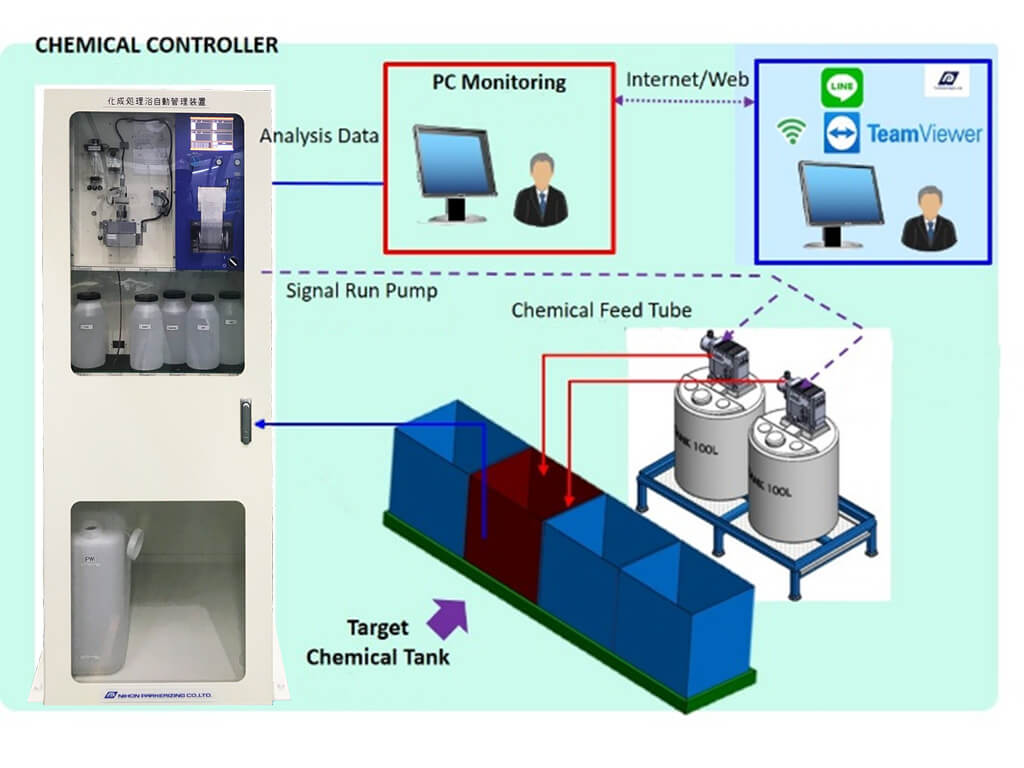

Chemical Controller

Chemical Controller is an equipment that has been developed to increase efficiency and quality control in production process with automation, according to the Industrial 4.0 concept. The automation including sampling, checking, replenishing and able to view real time data by online via wireless/internet system. Chemical Controller can install in variety process such as degreasing process, conversion process, acid pickling process and other processes, which can be modified or designed to meet to matching with customer process requirement as well. |

Get the info you’re looking for right now!

If you can’t find the answer you’re looking for, we’d love to hear from you – whether you’re curious about features, a sample trial, or even pricing—we’re ready to answer all questions a find the right products for you!

- Chemical analysis by the change of pH and color (colorimetric sensor)

- Automatic chemical control and supply by proportional calculation

- Automatic data collection and traceability system such as measured values, the amount of chemicals adjusted, etc.

- Real time/online checking information via internet system

- Full with indispensable functions and simple operation with touch-panel

- Error warning system

- Expect to reduce chemical consumption and labor cost

- Chemical Controller for Degreasing chemical

Automobile, Auto-part, Appliance production line - Chemical Controller for Surface condition

Automobile, Auto-part, Appliance production line - Chemical Controller for Phosphate chemical

Automobile, Auto-part, Appliance production line - Chemical Controller for Zirconium chemical

Appliance production line e.g. Refrigerator, Air conditioner - Chemical Controller for Acid pickling

Wire and pipe extrusion line

Product type

Check more of our Product / Process type specifications below.

Benefits of Carbonitriding Heat Treatment

Carbonitriding is one of the processes of gas heat treatment. The process involves the introduction of carbon and nitrogen into the surface of the steel. This process is similar to gas carburizing, which is a process in which carbon is infiltrated into the surface and carburized, then hardened by rapid cooling (Quenching) at a lower temperature. The difference between these two processes is the substance added to the steel surface and the temperature used.

Carbonitriding is a process in which carbon and nitrogen are simultaneously infiltrated into the surface of steel at a temperature of about 800℃ to 880℃, lower than ordinary gas carburizing (850℃ - 940℃). After the part has been heat-treated, then the quenching part is needed to immediately start. Quenching is also the critical step in the carbonitriding heat treatment which can be cool heated metal in water, oil, or air in order to obtain desired material properties.

You're probably starting to wonder how this difference affects your products. And why is carbonitriding a better alternative? Thai Parkerizing will answer your questions today.

Purpose of Carbonitriding heat treatment process

The purpose of carbonitriding is to create a hard, wear-resistant surface layer while maintaining the toughness of the underlying metal. The carbon and nitrogen atoms form nitrides and carbides in the metal, which are very hard and wear-resistant. However, the hardened case is not an additional layer on top of the steel. The carbonitriding process alters the top layer of the component so the original dimensions are retained. The process is suitable for non-alloy steel and low carbon steel that would not achieve a hardened surface in standard gas carburizing.