- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

- E-Service

|

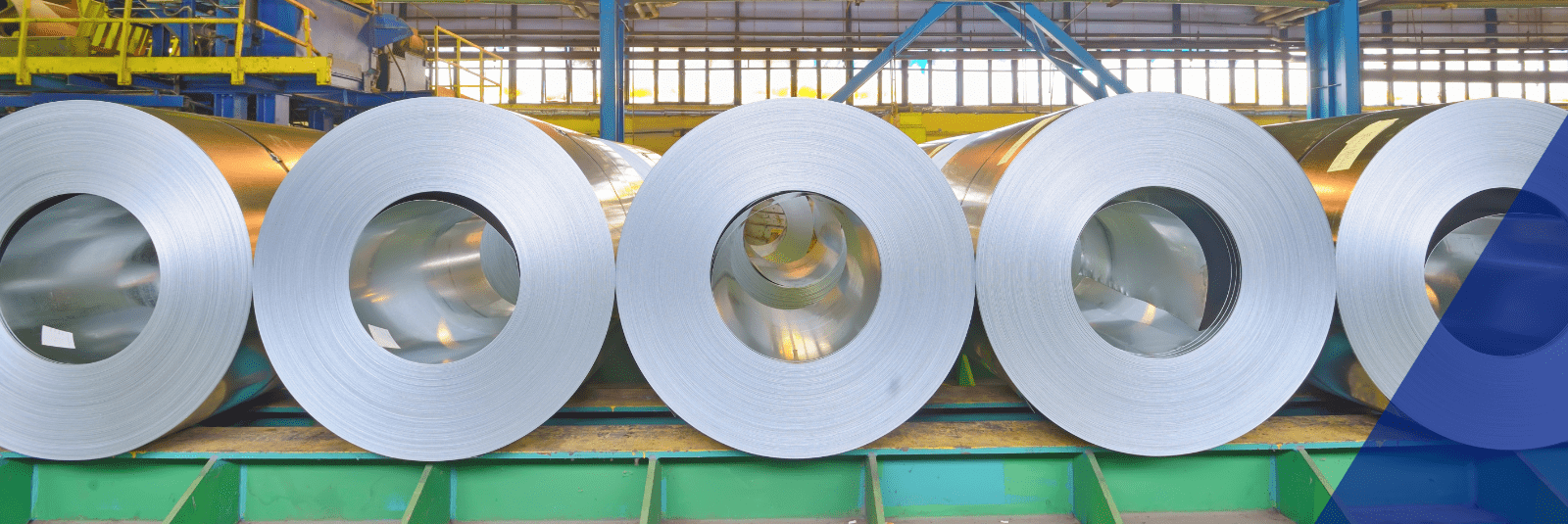

Rolling Oil

We supply emulsion type of rolling oil, to increase lubrication and reduce friction in the cold rolling process of the steel sheet and as a coolant. We have continuously developed rolling oil products with a focus on increasing efficiency of rolled at high speeds and reducing abrasion. In addition, the product does not contain prohibited substances such as Nonylphenol or other pollutants in order to be safe for the environment. Appropriate use of rolling oil will improve lubrication efficiency, reduce rolling temperatures, reduce quality problems on steel surface, and reduce energy costs. This not only reduces burden on the environment but can also leading to a reduction of the overall cost for customers. |

Get the info you’re looking for right now!

If you can’t find the answer you’re looking for, we’d love to hear from you – whether you’re curious about features, a sample trial, or even pricing—we’re ready to answer all questions a find the right products for you!

- High Lubrication and reduce friction

- Mill cleanliness and easy to clean

- Cold Rolled Steel Sheet (SPCC)

Product type

Check more of our Product / Process type specifications below.