- เกี่ยวกับบริษัท

- ผลิตภัณฑ์เคมี

- เครื่องควบคุมค่าเคมีอัตโนมัติ

- เคมีสำหรับงานทำสีและห้องพ่นสี

- เคมีเคลือบเหล็กแผ่น

- ผลิตภัณฑ์ล้างและทำความสะอาดผิวโลหะ

- แผงแลกเปลี่ยนความร้อน/ความเย็น (PLATECOIL)

- เคมีไฮโดรฟิลิก

- แมงกานีสฟอสเฟต

- เคมีเคลือบผิวระดับนาโน (PALLUCID)

- น้ำมันรีดเหล็ก

- ผลิตภัณฑ์ป้องกันสนิม

- ผงสบู่หล่อลื่น / เคมีหล่อลื่น (PULS)

- ไตรวาเลนต์โครเมียม / นอน-โครเมียม

- สังกะสีฟอสเฟต / เหล็กฟอสเฟต

- บริการรับชุบ

- บริการรับวิเคราะห์

- บทความ

- ข่าวสารและกิจกรรม

- ติดต่อเรา

- นโยบายความเป็นส่วนตัว

- E-Service

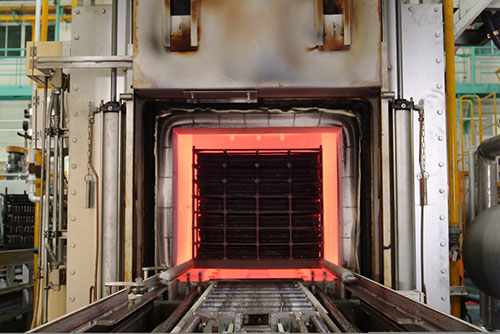

กระบวนการอบชุบทางความร้อน / ชุบแข็ง

Did you know that the mechanical and physical properties of metal can be changed by heat treatment? That's right! By heating and cooling metal, its hardness, strength, and ductility can be altered. Heat treatment is a process of heating and cooling metal to change its mechanical and physical properties. We provide various types of heat treatment at Thai Parkerizing Co., Ltd. to fulfill all the requirements of our client. This article is briefly talking about fundamental information on heat treatment. Let’s take a look!

Purpose of Heat treatment

The purpose of heat treatment is to improve the mechanical properties of a material by heating and cooling it in a controlled environment. The most common reason for heat-treating a material is to make it harder and stronger. Heat treatment can also improve the toughness and resistance to wear and tear.

Advantages of Heat treatment

There are plenty of advantages to heat treatment. Let’s see the brief benefits of heat treatment:

- Improve hardness, toughness, and impact strength

- Improve wear resistance ability

- Improve fatigue strength

- Become a more durable product

- Become easier to weld

- Prolong product’s lifespan

However, there are various types of heat treatment. Therefore, the benefits you will receive are also related to the process you have chosen.

Types of Heat treatment

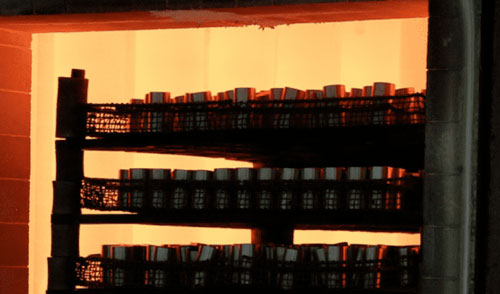

1. Gas Carburizing

Gas carburizing is a type of surface hardening that is used to increase surface hardness and toughness of mild or low alloy steel by heating the steel to 850℃ - 940℃. The process involves heating the steel to a temperature where carbon infiltrated into the surface and is carburized. The metal structure will change from austenite phase to martensite phase on the surface. Then the steel is hardened by rapid cooling (Quenching) at a lower temperature and then tempering to release stress at a temperature that is suitable for each application. The process results increase in surface hardness and toughness of the steel, making it more resistant to wear and tear.

Sometimes, it is necessary to prevent carburizing on certain areas of a part. Preventing carburization in selective areas can be done with mechanical masking or chemical coating (Botan process)

2. Gas Carbonitriding

Carbonitriding is a process in which Carbon and Nitrogen are simultaneously infiltrated into the surface of steel at a temperature of about 800℃ to 880℃, lower than ordinary gas carburizing (850℃ - 940℃).

After the part has been heat-treated, then the quenching part is needed to immediately start. Quenching is also the critical step in the carbonitriding heat treatment, which can be cool heated metal in water or oil in order to obtain desired material properties.

Since it can be quenched at a lower temperature than gas carburizing, deformation and distortion due to heat treatment can be reduced. Hence, the process is suitable for non-alloy steel and low carbon steel that would not achieve a hardened surface in standard gas carburizing.

3. Quenching and Tempering

Quenching and Tempering is a heat treatment process that changes the state of martensite structure by heating steel with a carbon content of 0.3% or more to the austenitizing temperature around 850°C and then rapidly cooled in water or oil.

Quenching is the process of heating the steel to a high temperature and then quickly cooling it in water or oil. This process makes the steel harder. Tempering is the process of heating the steel to a lower temperature and then slowly cooling it. This process makes the steel less brittle.

4. Gas Soft Nitriding

Gas Soft Nitriding is a thermo-chemical treatment that involves diffusion of both nitrogen and carbon to the surface of ferrous materials at a temperature of 540-590°C, but with more nitrogen than carbon, when compared to the carbonitriding process. The reason is that the gas soft nitriding process does not involve heating into the austenite phase first and then quenching to form martensite structure, which will result in minimum distortion and excellent dimensional control.

The process is beneficial for improving some abilities of metal products, such as hardness, wear resistance, fatigue strength, and corrosion resistance. This technique is suitable for all steels, except stainless steel.

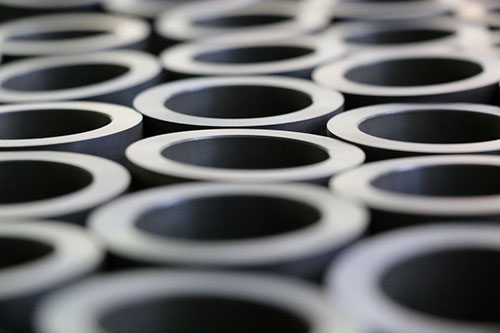

5. Salt Bath Soft Nitriding (ISONITE®)

Salt bath soft nitriding is an industrial surface treatment that can be used to improve surface hardness, wear resistance, and corrosion resistance of metals (except stainless steel). In addition, the process also improves the heat resistance of the steel. The process involves immersing the metal in a bath of molten salt at a high temperature. Carbon and Nitrogen are then diffused into the metal, which reacts to form a compound layer and diffusion layer of nitride on the surface.

ISONITE treatments can be applied to several types of metal material such as carbon steel, sintered metal, low alloy steels, stainless steels, cast irons and high alloy steels.

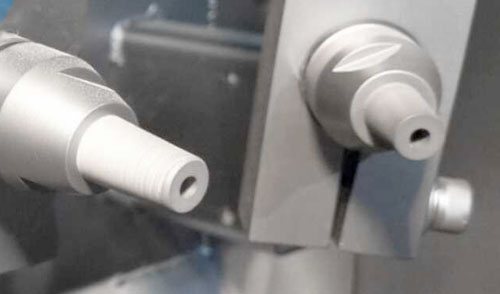

6. PVD

Physical Vapor Deposition (PVD) is a process of creating a thin film with high hardness. This film has low surface friction, excellent abrasion resistance, able to resist oxidation and corrosion resistance which helps to prolong product lifespan.

PVD coating technology is a physical coating under vacuum conditions to obtain a micron thin film on a metal surface. The hardness of coated film is higher than Tungsten carbide.

When compared to Hard chrome or Nitriding, PVD-coated films have higher hardness, can greatly reduce wear with a few microns of thin films and there is no worry about the diameter changed.

7. Shot peening

Shot peening is a cold-working process used to produce a compressive residual stress layer and modify the mechanical properties of metals.

The process will improve the steel’s fatigue resistance, results in delayed crack initiation and retarded crack propagation from the surface. It also prevents stress corrosion failures and prolong product life span.

FAQ's

A: Heat treatment is a process that is used to change the physical and/or chemical properties of a material. The material can be changed by heating it to a certain temperature and then cooling it. Heat treatment is often used to make materials harder or softer. It can also be used to change the color of the material.

A: There are many types of heat treatments, but all of them are important in one way or another. The main purpose of heat treatment is to change the microstructure and properties of a material. It can make metals harder, tougher, and more resistant to wear and tear. Heat treatment is also used to remove residual stresses from components, which can improve their performance and lifespan.

A: Definitely, the answer is metals. The most important property of metals that anyone cannot deny is malleability. This special property enables the metal to transform its shape in the way we want. In addition, we can add more properties such as hardness, wear resistance, or fatigue resistance through the heat treatment process. Heat treatment is much more important to the metal used in automobiles, motorcycles, electric appliances, and so on.

Benefits of Thai Parkerizing Heat Treatment Services

There are a number of different heat treatment options to choose at Thai Parkerizing company. The usage of each option depends on the properties required for the product’s function. It’s essential to work with a company that understands your products and your requirements. Thai Parkerizing can be the one for you! We will analyze and choose one of our heat treatment services, one that best suits your specific needs. To reinforce your trust in our services, we analyze the quality of the product every time after the process. Then, we will deliver it safely toward your hands.